ROI with RFID enabled WIP Tracking

Knowledge of product status in the assembly process can help in planning output, improving capacity utilization and enhancing product quality. Information about the time spent by a product in each process step can help to determine product costs more accurately. In addition, some steps in the production process (e.g. painting and drying) require a predefined amount of time. RFID technology can help machines to control those times automatically. Benefits of RFID enabled WIP tracking are:

- Ability to manage multiple products within a single assembly line

- Attaching recipes to products

- Tracking the progress in real-time on the floor

- WIP data across all processes and stations

- Ability to manage production flow with closed loop data management

- Ability to manage line speed based on production rates as the RFID tags can be updated in real time across the line

- Real time checks at all stations manage production

- Tracking on time bound processes

- Real time availability of work performed data on every item enables checks such as "curing" or "baking" of products

- Stations can check timings and reject parts based on process criteria

- Ability to manage specialty options within a production line

- RFID tags can maintain the assembly route and track special operations that might have been performed on the product

- Comprehensive WIP data across all stages of production

- Traceability to individual stations or operators who worked on the product

Proposed System Overview

WIP Systems, these shop floor data collection systems are typically used whenever "work" (something that's being manufactured, fabricated, or repaired) travels between a number of workstations or departments. Using bar codes (or RFID) to identify the work order or actual work item, personnel, performed tasks, conditions, and other valuable data, information can be easily and efficiently recorded and amassed.

In somewhat simple terms, a WIP system might record and responses to:

- What (what thing or job?)

- Where (where it is/was it located?)

- Task or operation (what work was done?)

- Who (who did the work?)

- Duration (how long did it take them?)

- Output (how many units were produced and/or scrapped?)

Solution Outline

- Every item (Car) is tagged by the barcode- VID

- Import those data into application (Importing DATA from the SAP)

- Every SKID and HANGER is tagged by RFID

- One or more Scanner is mapped with the every SKID

- On First SKID, user read barcode data and map to the SKID Tag

- Meanwhile scanner read the tag and update the server about car on this skid.

- On item switching by one skid to another through hanger, exit scanner of first skid, update log with exit time of car from skid and entering scanner of second skid update his tag by new VID.

- System will manage log, archive log, OLAP execution for all analysis and statistics.

Benefits

- Complete real-time information about WIP

- Facilitates exact output planning

- Flexible use of machines

- Supports continuous improvement of production process

- Integrated total quality control

- Faster assembly with automatic quality checks

- Better capacity utilization of assembly stations &reduced cycle times

Proposed Solution

Solution is divided in four different Phases:

- Tags all the Items with RFID Tags

- Installing RFID Readers

- Track WIP with the help of proposed system automatically

- Centralize Data Storage, Reports and Analysis

Our Proposed System features are as under:

- Fully Automatic &Authentic System

- RFID + GPRS (Online / Offline Processing)

- Importing data from Existing System

- No need to maintain multiple system

- RFID antenna mapping with location

- System should display VID with current location status along with time.

- Manage the ideal skid and track time for same.

- GUI Implementation makes a system easier to operate and provide more visualization.

- WIP log management

- According to logged data, system will generate many statistical reports.

- Location wise WIP tracking and tactical analysis

- By OLAP system created 3 Dimensional Analytics

- History Management

- Data Archive Facility

- Synchronization facility with Handheld Smartcard tracker

- Smart Graphical User Interface to represent location wise real-time inventory tracking information

- User Friendly PDA software Application

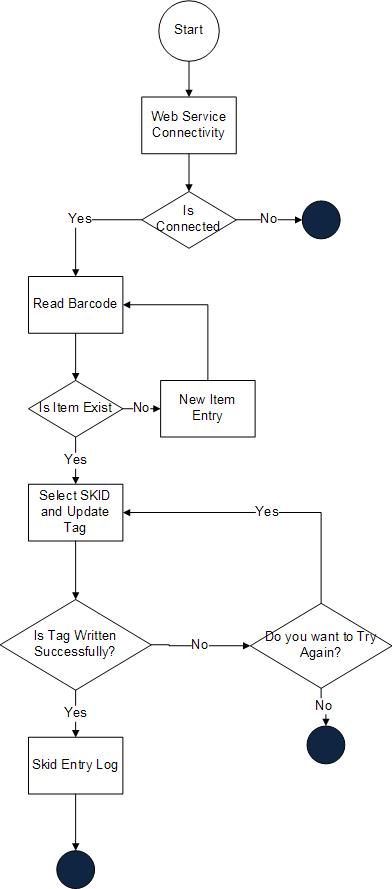

Flow Chart

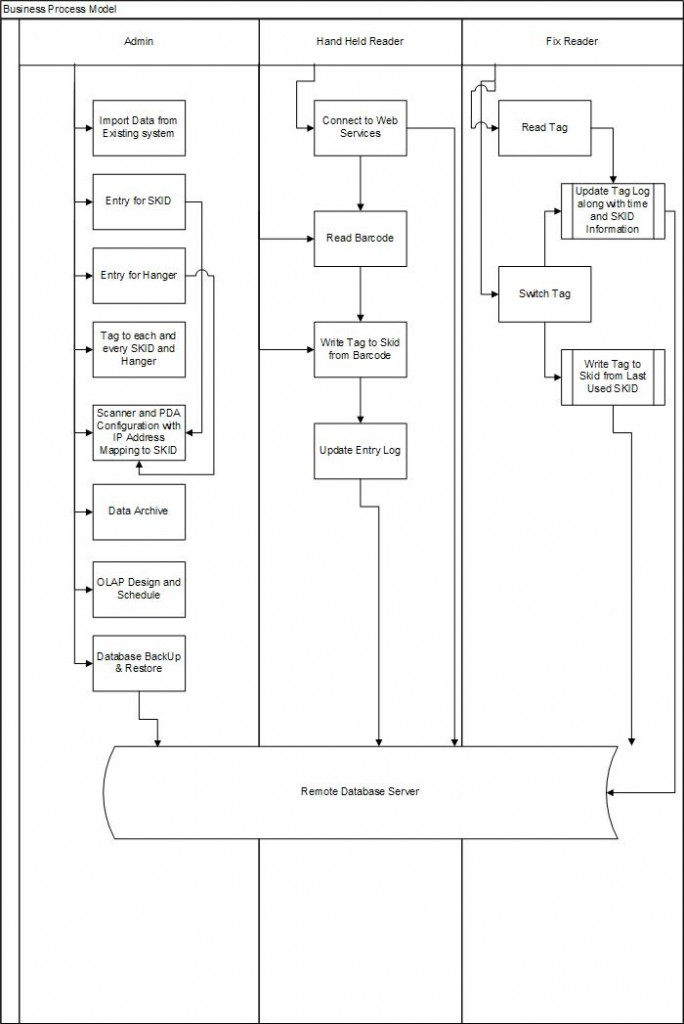

Proposed Business Process Model

|